Laser Engraving Machine

| Price: |

US $ 3000-7000/Piece |

| Trade Terms: |

FOB,CFR,EXW |

| Min Order: |

1set |

| Pay Type: |

L/C,T/T,Paypal |

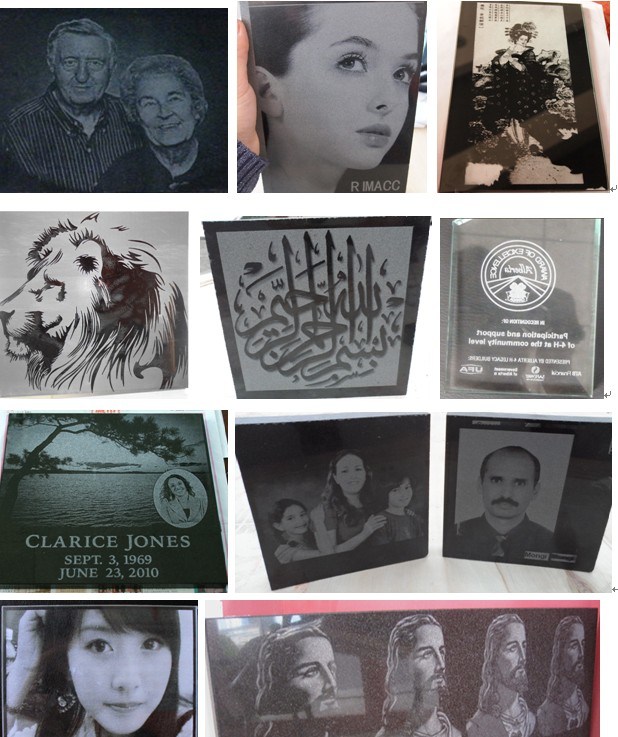

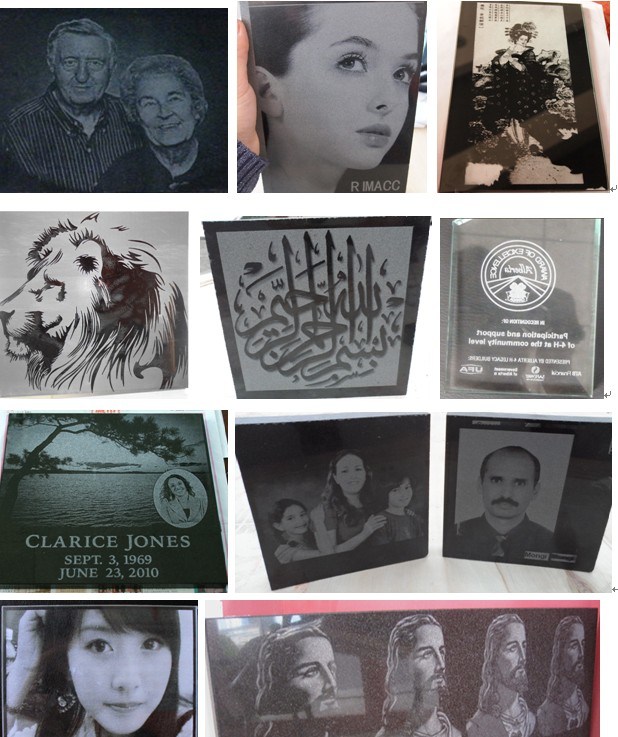

Tombstone Marble Granite Laser Engraving Machine/ marble engraving machineJQ1060 Laser engraving machine with separable design

Performance Features

1). The upper part and the under part of the machine are separated. The upper part can put on large and thick marbles/stones/granites, etc. directly.

2). The machine is with double up-down worktables. The upper part and the under part can move up and down automatically, which are very convenient for thick material.

3). Very useful for small house doors.

Applicable Industries

Model Industry (construction models, aviation and navigation models and wooden toys), advertisement, decoration, art crafts, electronics and electric appliances, etc.

Applicable Materials

Non-metal materials such as acrylic , crystal , plastic , metal coating , painted metal , organic glass , wood planks(light planks) , marble , carton , glass , fabric , leather , bamboo ware , double-color boards , paper , shells , coconut shells , ox-horns , resin animal grease , ABS boards , lamp shade , ect.

Laser Engraving Machine Technical Specifications

|

Item / Model

| JQ-1060

|

Cutting area

| 1000 x 600mm

|

Laser power

| 60w

|

Laser type

| CO2 sealed laser tube,water-cooled,10.6um

|

Engraving speed

| 0-60000mm/min

|

Laser Output

| 1-100%software setting

|

Resetting positioning accuracy

| ≤±0.01mm

|

Power supply

| AC 110 - 220V ± 10%, 50 - 60Hz

|

Operating temperature

| 0 - 45°C

|

Operating humidity

| 5 - 95%

|

Min. shaping character

| English 1.0mm x 1.0mm

|

Graphic format supported

| BMP, PLT, DST, DXF, AI

|

Software supported

| Tajima,CorelDraw, PhotoShop, AutoCAD

|

Driving system

| stepper

|

Cooling mode

| Water-cooling and protection system

|

Equipment Dimensions

| 1050mm*750mm*970mm

|

Net Weight:

| 150kg

|

Optional Spare Parts

| Up-down clump, Rotary System, Honeycomb table

|

Recommended Spare Parts

| Laser Tube and Lens

|

About us - Jinan JinQiang Laser CNC Equipment CO., LTD

Workshop & Showroom

Workshop is the product of intense laser manufacturing center gold, bear manufacturing various types of laser equipment. Factory workshop area of 5075 square meters, the plant's existing staff of 46 people, including management staff4, the worshop has three steps, the 10 team composition, with annual production of non-metallic series 4030, 6040, 9060, 1290, 1390, 1490,; cutting 1325, 1525, 1530, 1610, 1630; metal series 1325-YAG, 1325-fiber, 1530-fiber and other conventional and non-standard laser annual output of 3,000 sets of CNC equipment manufacturing capacity.

Exhibition in whole world

We participated in many international exhibitions, for example: Shanghai Exposition, Beijing Exhibition, Munich Exposition in Germany, etc.

If you are distributor, JQ laser hope to cooperate with you and participate your local fair, for helping you to open and occupy the market.

CE, FDA, SGS, etc

Certification of JQ Machine

JQ laser machine have passed most testing and comply with the international standard. With CE, our machine sell well in Europe; there is no problem to export machine to America with FDA; don't worry about quality, we can show you SGS certificate; if you want import machine to Egypt or some strict countries, we can provide fumigation certificate.

FAQ

1. Q:Are you a factory or trading company?

A: We are a factory

2. Q:Where is your factory located? How can I visit there?

A:Our factory is located in Jinan City, Shandong Province, China, about 4 hours train from Shanghai .

All our clients, from home or abroad, are warmly welcome to visit us!

3. Q:How can I get some samples?

A: We are honored to offer you samples.

4. Q:How does your factory do regarding quality control?

A:Quality is priority. JQ people always attach great importance to quality controlling

from the very beginning to the very end.

Our products has gained CE, FDA authentication.

Selecting your Laser Cutting Machine

Before you start calling companies and making your decision on who you are going to go with, you should know the basic questions and answers that are required to make sure you are getting the right laser cutting machine for your workshop.

1. What kind materials will you need to cut?

Depending on the type of materials that you are cutting with decide what kind of laser is required. If you are only cutting thin metals than a fiber laser will be more efficient, though if you are cutting plastics or woods then you will need a CO2 lasers. (There are material restrictions on each laser source)

2. What is the common size of sheet metal that needs to be cut?

This will determine the size of your cutting bed also be sure that you will have enough room in your workshop to fit. Common size for laser cutting is 1.5m Width by 3m Length.

3. What is the thickness of the material do I need cut?

The thickness of the material will determine the power of the laser source, as the thicker the material the more power is needed to be supplied.

4. Do I need CAM Software?

Every machine is equipped with computer controlled laser software. CAM Software is a very important piece of software for your machine, it will give you the ability to easily operate your machine and provides you with nesting capabilities to save you on consumables and materials with its intelligent design.

5. What are the cutting speeds?

The speed of machine will vary depending on the size of material that is cut, though the speed of the cut will give you the effectiveness of the machine you are purchasing and is both determined by the laser source you will be using and the machines capability.

6. What do I need in my workshop?

Before you purchase a machine you need to look at a few factors in your workshop, firstly if you have the space for the laser machine, secondly if you have the power in your workshop to handle the machine (ask a Farley rep for the floor area and power required).

7. Is there a local service team?

There is less problem for laser machine, most are operation problem - our engineer provides on-line training; any technical question, they can resolve on-line or by remote-assistance. JQ engineer is available to visit your factory and provide face-to face assistance or training. There are 13 engineers in JQ Laser to help foreign customers and domestic customers.

If you have the answers to these questions then you will be able to select the correct laser cutting machine for your workshop

| Prod Model: |

JQ1060 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Engraving Machine Type: |

Laser Engraving Machine |

| Usage: |

Stone |

| Power: |

Small Power |

| Drive Type: |

Stepper Drive |

| Certification: |

SGS, CE |

| Laser Type: |

CO2 |

| Control: |

Automatic |

| Current: |

AC |

| Condition: |

New |

JQ company manufactures more than fifty different kinds of machines types, including quick speed laser engraver and cutter, big working table machine type, stone engraving machine, logo cutter, fabric engraver and cutter. Glass engraver, metal cutter and etc. The machines are widely used in many different fields and industries, such as advertisement, package. Metal sheet cutting. Kitchen ware,

Machine body manufacturing, ship building, aerospace equipment, military products, medical equipments, computer case, light fitting, arts and gifts, nonferrous metal manufacturing and marking, sports equipment, upholstered furniture.

Besides domestic market, the machines are also sold to Hundreds of international countries. Such as United States, Germany, France, Middle-EasLindia, Russia, Brazil. Thailand, Malaysia, Mexico, Korea and so on.

Our company is guided by the market-oriented concept as well as masterful technique, and regards "good service and customers' benefits" our rules. With technical development, and many years of research, our products are improved day by day, always being in the lead position

Our philosophy is "Golden Quality, The Best Technique and Good Faith". We are trying to be a well-known company at home and abroad with the perfect and considerate after-sales service system.

We welcome customers from all over the world to cooperate with us and achieve win-win. Please feel free to contact us for further information.

Our company uses our good service for market, based on high product quality, and developing on technology, making progress by innovation. JQ is very glad to be at your service!