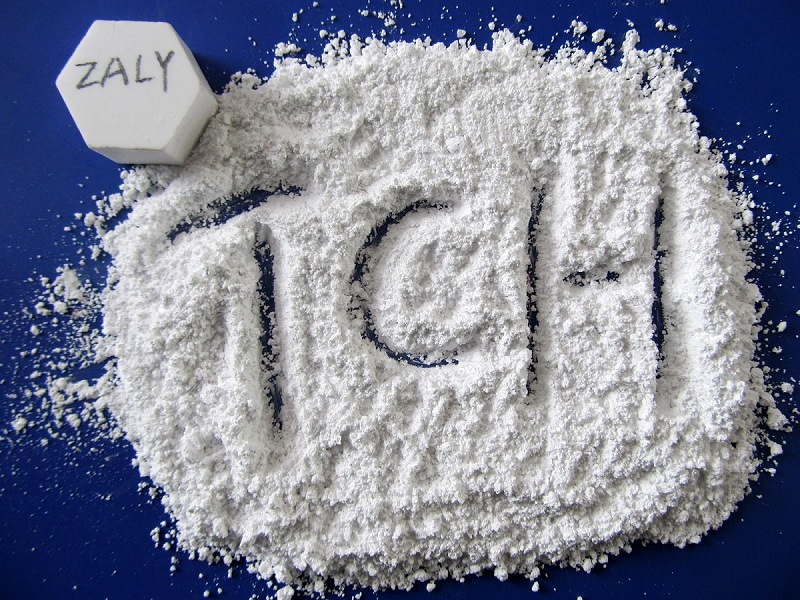

1. Technics: Calcined temperature beyond 1300C, the alumina powder be calcined without Boron, Ultimate crystal size 3-5um.

2. Application: TCH-1/TCH-2/TCH-3 is good for producing electronic alumina ceramic/wear resistant ceramic(alumina wear tile, alumina ceramic brick, alumina ball)/alumina ceramic substrate.

3. Payment Term: TT /LC AT sight.

4. Delivery time: Within 2 weeks to ship since the date we receive your deposit or L/C at sight.

5. AI2O3>99.7% Na2O <0.3% Fe2O3<0.024% SiO2<0.019% TiO2<0.008%.

6. Loss weight when burning<0.2% Density=3.96g/cm3 a-Al2O3>93%

Medium particle size(D50) 75um Ultimate crystal size 3-5um

BET specific surface area 1.0 m2/g

Characters:

This product is refined from high quality calcined alumina by scientific confecting, rubbing, pulping, spraying, drying. The product is charactered by reasonable particle size, moderate strength, good fluidity, low sintering temperature, easy demolding.

Alumina Spray Prilling Powder

Ceritificates: SGS, ISO

AL2O3 Highest Purity 99.9%

High density

Low sinteresting temperate

|

Type |

Model |

Al2O3 |

Na2O |

Fe2O3 |

SiO2 |

TiO2 |

LOI |

True Density |

a-Al2O3 |

D50 |

Primary Particle Size |

Specific Surface |

|

Unit |

≥ % |

≤% |

≤% |

≤% |

≤% |

≤% |

g/m3 |

≥ % |

um |

um |

m2/g |

|

Dry pressing/CIP series |

TCH-101 |

99.7 |

0.08 |

0.02 |

0.018 |

0.006 |

0.15 |

3.96 |

96 |

75 |

2--3 |

0.6-0.8 |

|

TCH-102 |

99.6 |

0.1 |

0.02 |

0.018 |

0.006 |

0.15 |

3.95 |

95 |

75 |

2--3 |

0.6-0.8 |

|

TCH-103 |

99.5 |

0.2 |

0.02 |

0.018 |

0.006 |

0.2 |

3.95 |

95 |

75 |

2--3 |

0.8-1.0 |

|

TCH-105 |

99.4 |

0.3 |

0.02 |

0.018 |

0.006 |

0.2 |

3.93 |

93 |

75 |

2--3 |

0.8-1.0 |

|

Injection moulding |

TCH-213 |

99.5 |

0.25 |

0.02 |

0.018 |

0.006 |

0.15 |

3.95 |

95 |

75 |

3--4 |

0.5-0.6 |

|

TCH-211 |

99.5 |

0.25 |

0.02 |

0.018 |

0.006 |

0.1 |

3.96 |

96 |

75 |

3--5 |

0.5-0.6 |

|

Refractory series |

TCH-31 |

99.4 |

0.3 |

0.02 |

0.018 |

0.006 |

0.15 |

3.92 |

90 |

75 |

2--3 |

0.1-0.8 |

|

TCH-30 |

99.5 |

0.25 |

0.02 |

0.019 |

0.008 |

0.1 |

3.95 |

95 |

3--5 |

2--4 |

1.0-1.2 |

|

TCH-33 |

99.4 |

0.25 |

0.02 |

0.018 |

0.006 |

0.15 |

3.95 |

95 |

43 |

2--3 |

0.9-1.0 |

|

TCH-003 |

99.4 |

0.3 |

0.02 |

0.018 |

0.006 |

0.13 |

3.95 |

95 |

4 |

3--5 |

1.0-1.2 |

|

TCH-35 |

99 |

0.25 |

0.02 |

0.02 |

0.006 |

0.2 |

3.9 |

90 |

43 |

3--5 |

0.9-1.0 |

|

Active α-Al2o3 |

TCH-5H |

99.4 |

0.15 |

0.02 |

0.15 |

|

|

3.95 |

95 |

1 |

|

|

|

TCH-5L |

99.4 |

0.15 |

0.02 |

0.15 |

|

|

3.93 |

93 |

0.8 |

|

|

|

Polishing series |

TCH-61 |

97 |

0.1 |

0.1-0.2 |

0.18-2 |

|

|

3.95 |

95 |

40-60 |

|

|

|

TCH-62 |

97 |

0.1 |

0.1-0.2 |

0.18-2 |

|

|

3.95 |

95 |

4--5 |

|

|

|

TCH-63 |

98 |

0.1 |

0.05-0.6 |

0.18-0.2 |

|

|

3.97 |

95 |

4--5 |

|

|

|

Glazing series |

TCH-7 |

99.6 |

0.2 |

0.02 |

0.018 |

|

|

3.95 |

95 |

55 |

|

|

|

TCH-703 |

99.6 |

0.2 |

0.02 |

0.018 |

|

|

3.95 |

95 |

15 |

|

|

|

TCH-713 |

99.6 |

0.2 |

0.02 |

0.018 |

|

|

3.95 |

95 |

4 |

|

|

Lianyungang Zhong Ao Aluminium Co. Ltd (AIZA)

Our Products:

Alumina Ceramic Ball

Alumina Ceramic Lining

Alumina Ceramic Cylinder

Alumina Wear Tile

Alumina Ceramic Beads

Alumina Ceramic Nozzle

Alumina Ceramic Ring

Insulation Ceramic

Customized Heterotypic Technical Ceramics

AIZA is a Lianyungang based Sino-Foreign joint venture corporation. It is a Chinese producer of calcined alumina and a manufacturer of alumina ceramics, such as alumina ceramic ball, alumina ceramic cylinder, alumina wear tile, ceramic insulator, ceramic element, ceramic beads, and other insulation ceramics with self-prepared material as well as German and Japanese material.

Since its creation, AIZA has served most of Chinese customers, Nanjing Huade, Zhuzhou Xianghuoju, and Chaozhou Sanhuan, which are eminent manufacturer of spark plug and advanced ceramic in China. Its "TCH" brand calcined alumina is well accepted by our customers.

In 2008, AIZA purchased 70 key equipment from Shanghai Morgan Matroc after its closure in China. The equipment includes isostatic press machine, dry press machine, hot press cast machine, ball mill, alumina spray prilling tower (centrifugal and pressure), polishing machine, etc. The equipment has been successfully installed in our factory by the end of 2008. Now, AIZA have succeeded in establishing itself as sole Chinese manufacturer of ceramic nozzle by isostatic dry bag pressing process. Besides, the most experienced technical engineer of former Shanghai Morgan Matroc also joined us, which is the precious source of our confidence of ensuring products quality.

TQC Procedures and ISO 9001: 2000- Certification

Our experienced QC will supervise the production and check the quality before delivery. We conduct TQC procedures according to ISO 9001: 2000-certified guidelines. In order to ensure better quality, we carry out five processes below:

1. Material inspection

2. Semi-manufactured goods inspection

3. Itinerary inspection

4. Finished products inspection

5. Shipment inspection.

Material Adopted:

Alumina

Zirconia

Steatite

Alumina-Zirconia

Technologies Adopted:

Dry Pressing

Isostatic Pressing

Heat Press Cast

Flowchart of Customized Service: Drawing Received---Researching and Tooling---Sample Collecting and Testing---Sample Accepted---Order Confirming.