Emery Powder of Green Silicon Carbide F600

| Price: |

US $ 555-1460/Ton |

| Min Order: |

5/Ton |

| Pay Type: |

L/C,T/T,D/P,Western Union,Paypal |

emery powder of green silicon carbide F600

Introduction of the silicon carbide:

Silicon carbide is made of quartz sand, stone tar (or coal), wood chips and other raw materials in the resistance by high temperature smelting, silicon and carbon bonds made of ceramic compounds. Silicon carbide exists in nature in the form of rare minerals such as mozanite. Since 1893, silicon carbide powder has been used extensively as abrasive. The sintered silicon carbide powder can provide hard ceramic-like silicon carbide particles and can be used in materials such as automotive brake pads, clutches and ballistic vests that require high durability, such as light-emitting diodes, early radio detectors Classes are also used in the manufacture of electronic devices. Silicon carbide is now widely used in the manufacture of high temperature, high voltage semiconductors. By lely method to grow large pieces of silicon carbide single crystal. The gemstone of artificial mulberry is obtained by cutting the bulk silicon carbide single crystal prepared by the Lely method.

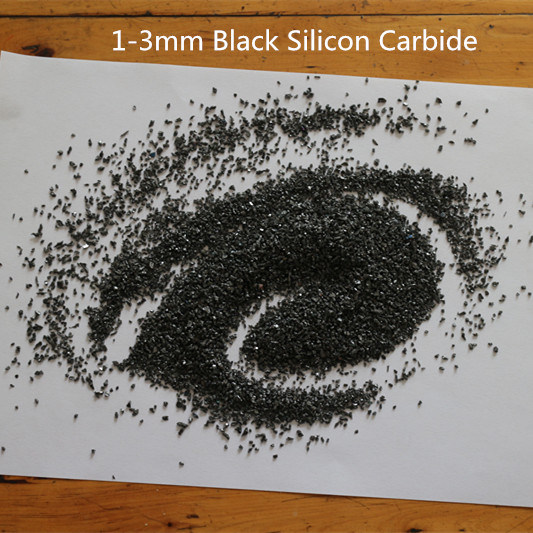

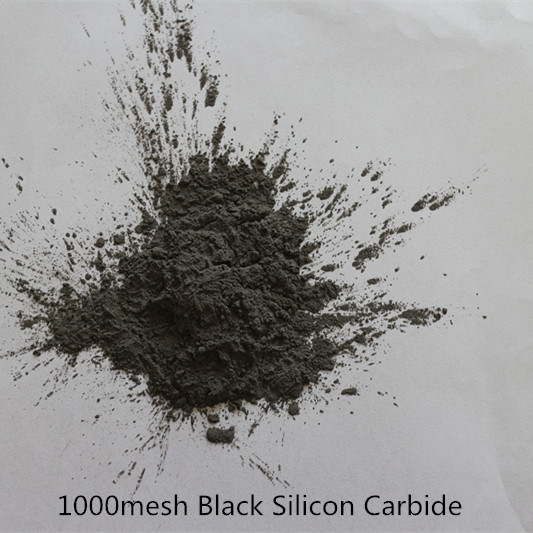

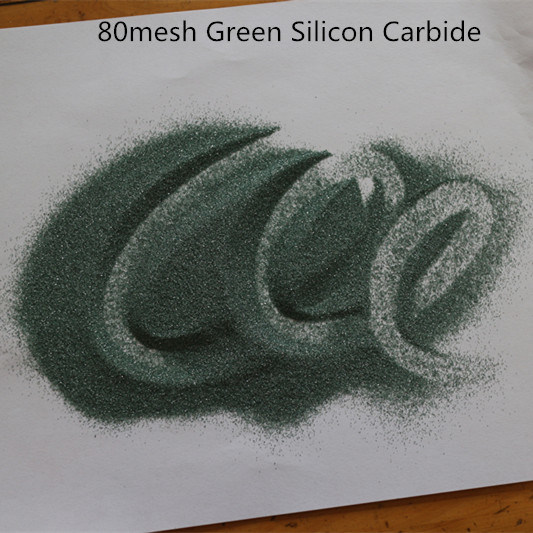

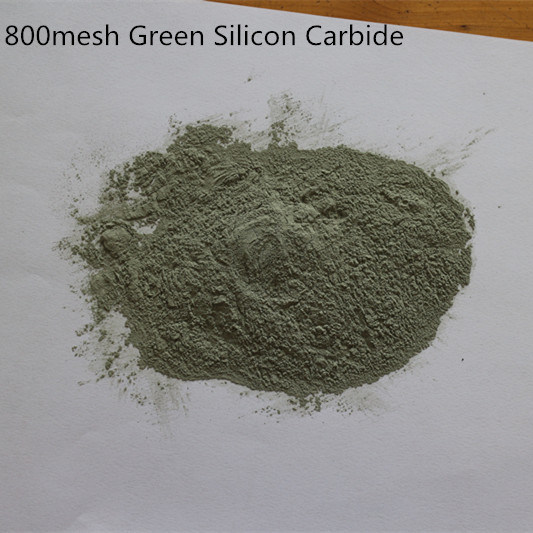

At present, China's industrial production of silicon carbide is divided into black silicon carbide and green silicon carbide two, are hexagonal crystal, green silicon carbide and black silicon carbide is basically the same, but the raw materials and manufacturing processes are produced, the product was green translucent body , Hardness, purity are better than black silicon carbide.

Commonly size:

Section of sand: 0-1, 1-3, 3-5, 5-8mm

Granular: 16, 20, 24, 30, 36, 46, 60, 80, 100, 120, 150, 180, 200, 220, 320mesh

Powder: 325, 400, 600, 800, 1000, 1200, 1500, 1800, 2000, 2500, 3000mesh

Density: 3.85g/cm3. Bulk density: 1.72-1.95g/cm3.

Appearance: Black or green crystal

Features of the silicon carbide:- High hardness.

- Good thermal conductivity.

- Small thermal expansion coefficient.

- Chemical stability.

- Good wear resistance.

Usage of the silicon carbide:

Usage of the silicon carbide:

Firstly: Silicon carbide is mainly used as abrasive in manufacturing grinding wheel, abrasive paper, abrasive belt, abrasive, grinding, grinding head, grinding paste, etc.

Sic grinding tool can be used in the manufacture of consolidation, coated abrasive grinding and freedom, to the processing of glass, ceramic, stone, jade, cast iron, stainless steel, floor tile and some non-ferrous metals, hard alloy, titanium alloy, high speed steel props and grinding wheel etc.

The second: refractory materials (silicon carbide powder, silicon carbide particles)

Silicon carbide as inorganic nonmetallic materials with high temperature resistant, wear resistant characteristics of silicon nitride combined with silicon carbide products can be used in the blast furnace ceramic cup, etc.In air brick as ladle with magnesia carbon brick, aluminum silicon carbide can also act as antioxidants added.

Made of silicon carbide refractory plate high crushing strength, long service life, low thermal capacity, low thermal conductivity.The brittle material, good toughness;Good flatness, size accurate,Easily cut installation, construction is convenient;Excellent resistance to wind erosion performance;Continuous production, uniform fiber distribution, stable performance;Excellent sound-absorbing noise reduction performance.

Third: steel making, casting industry (particles of silicon carbide, silicon carbide, silicon carbide, silicon carbide powder)

Silicon carbide as steelmaking deoxidizer can make molten steel quality is stable, and has fine grains, remove steel always harmful impurities, after using molten steel casting temperature, casting are of good quality and low cost per unit.

Silicon carbide can be all alternative ferrosilicon and recarburizer FeALSi dosage decreased, which can effectively reduce the cost of steelmaking.

Decomposition of silicon carbide at high temperature and oxidation is exothermic reaction process, positive pressure in the furnace is strong, and can guarantee lower sulfur content.

Fourth: photovoltaic industry, polishing, grinding, high-tech research and development, and other industries (silicon carbide micro powder)

Silicon carbide powder is mainly used for refractory products manufacturing, and foam ceramic industry, solar silicon original cutting, crystal cutting, grinding, car engine manufacturing, special coating industry, plastics modification, desulfurization, power supply, environmental protection industry, etc.

Specification of the silicon carbide:| SiC indicator | Date |

| Size | 0.1, 1-3, 3-5, 5-8mm

W#: 325, 400, 600, 800, 1000mesh

F#: 16, 20, 24, 30, 36, 46, 60, 80, 100, 120, 150, 180, 200, 320mesh |

| Density | 3.12g/cm2 |

| SiC | 98.5% |

| Free carbon | 0.2% |

| Fe2O3 | <0.6% |

| Hardness | 9.6 |

Packing: 25kg/bag, 24T/20ft

| Sic: |

98.5% |

| Free Carbon: |

0.2% |

| Specific Gravity: |

3.12g/cm3 |

| Size: |

16-3000mesh |

| Sample: |

Free |

Gongyi Qianjiaxin Refractory Co., Ltd is the most experienced producer of abrasive. Such as the brown fused alumina, white fused alumina, black fused alumina, silicon carbide, walnut, garnet, corn COB, quartz silica sand and so on.

Gongyi Qianjiaxin Refractory Co., Ltd has become an industry leader through our commitment to meet the needs of our customers. By finding the best solution for each customer, we have developed over 50 different grades of abrasive as well as complete systems and services. We back our products and services with exemplary technical support to deliver purification solutions based upon the use of abrasive.

What's more, our factory also produce other products. Such as activated carbon, water filter materials, refractory and so on. At present, our factory have more than 300 kinds of products. We have the production line of each product. Welcome to our factory to visit.