Categories

Categories

| Price: | US $ 198000/Set |

|---|---|

| Min Order: | 1/Set |

| Pay Type: | L/C,T/T,D/P,Western Union,Paypal |

Genyond is a group company which is speciallizing in extraction machine design, production and installation. Our head office is in Shanghai, China. It has 6 factories and 4 subsidiaries in China.

Our main products are food and beverage dairy machine, medicine machine, chemicals machine, filling and packing machine and so on. For more details, please visit sino-machine.en.alibaba.com.

YOU ARE WELCOME TO VISIT OUR COMPANY AND FACTORIES!

| Type | Margarine and Shortening processing machine |

| Material | Stainless steel SUS304 |

| Speed | Adjustable |

| Vacuum | 500-4000L |

| Effect | Oil separation |

| Application | Margarine Shortening |

| Our name | Margarine artifical milk cream Shortening |

| Product Keywords | GYC Margarine artifical milk cream Shortening complete line production processing plant machinery machines equipment making machine for bread cook cooking |

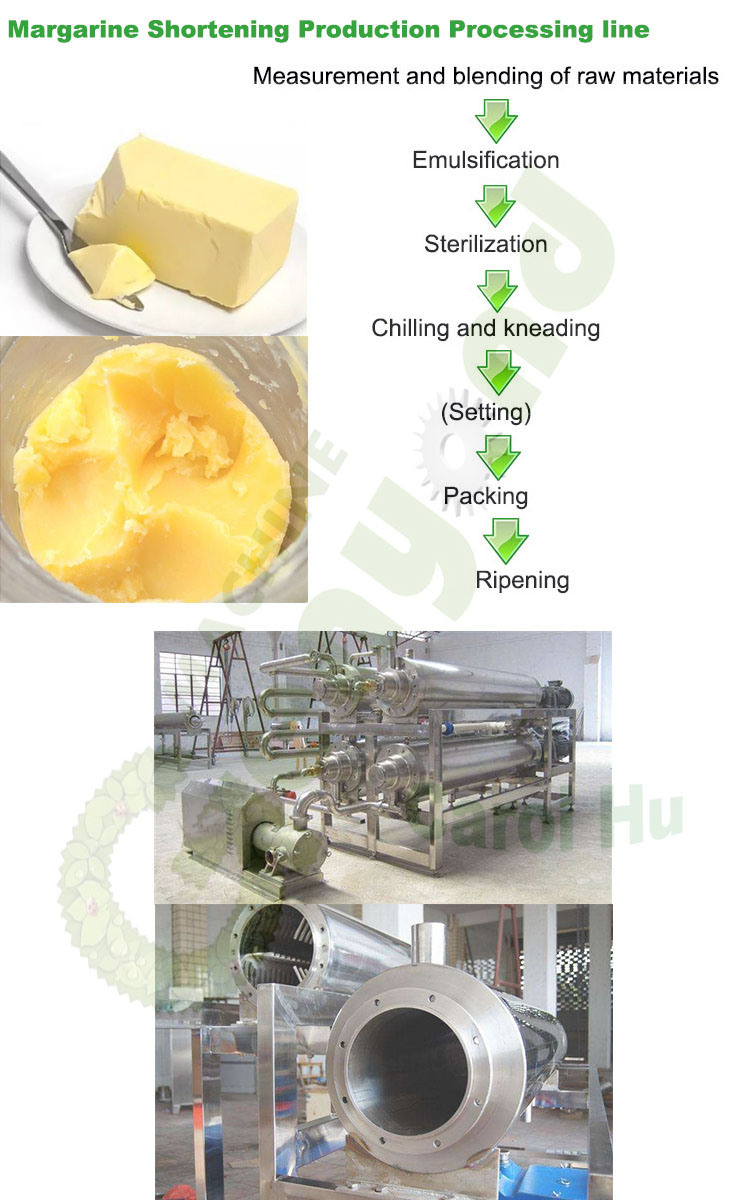

This system is the production of margarine, shortening and other main equipment oil products, mainly by the rapid cooling system (unit A), hot water circulation system, kneading shaft system (unit C), configuration, emulsifying tank, tank filling machine, refrigeration system, pressure pump and other components, so as to achieve the purpose of oil production.

When the emulsion enters the unit A of the quench system, the material is frozen and crystallized. When the scraper is constantly stirred, it is fully kneaded to play a better homogenization effect. Under the operation of the A unit, the material formed a semisolid with a temperature of 12 C ~14 C and a pressure between 1.5Mpa~2.0Mpa. The oil semifinished products containing crystal nuclei enter the kneader and grow in the crystal for a period of time. If the semifinished oil is made in a static state, the crystalline structure of solid grease will be formed, with a large hardness and no plasticity. To get a certain plastic product, we must knead before forming the overall network structure, and break the net structure formed before, so that it can recrystallize, reduce the consistency and increase plasticity. The kneading machine stirred the semi finished oil fully and kneaded (adjustable speed 50~300rpm/min) and formed the crystallization slowly. Due to the crystallization heat generated by crystallization (about 50kcal/kg), the friction heat generated by stirring causes the material temperature of kneading machine to rise and make the crystal soft. The grease produced by this system is soft, delicate and bright in appearance, which is the best choice for making oil products.

Our exhibition

Because most of our machines are non - standard, we will arrange production immediately after the payment is received. The delivery date is about 60 days.

01

We are factories, specializing in the design and manufacture of fruits and vegetables, beverages, dairy machinery, essential oil refining equipment, filling and packaging equipment.

02

The price is negotiable. It can be changed according to your quantity or package. When you are making an inquiry, please let us know the quantity you want.

03

The minimum order quantity is 1, the specific products please contact us!

04

We are very confident in our products,and we pack them very well,so usually you will receive your order in good condition.The warranty period is 12 months.

05

L/C,T/T,Western Union or 30%T/T in advance

06

The quality of our products meets all kinds of certification, and our service is also satisfied with you. Welcome to China to visit our factory at any time!

Our Advantage

Shanghai Genyond is the most professional manufacturer and distributor for rolling model encapsulation machine in China and we are the fore goer of encapsulation machine manufacture in domestic. We are mainly engaged in the development production and sales of encapsulation machine and related products. We have been sold to more than 100 domestic enterprises more than 400 sets of encapsulation machines, our products have occupied more than 80% share of the domestic market. And we have been exported to the United States, Australia, France, Peru, Yemen, Malaysia, Singapore, Canada, New Zealand, Indonesia, Myanmar, the Philippines, Taiwan and other countries and regions.

We have nearly 20,000 square meters, which registered capital of 20 million, and had total assets of 130 million, Company had more than 400 employees. The technical staff composed of 40 master's or doctor's degrees,138 bachelor's degrees. Our company passed the ISO9001 QUALITY, and a number of products certificate such as China quality mark certification and CE certification.

| Prod Model: | GYC049 |

|---|---|

| Advantage: | Automation |

| Capacity: | 500-4000kg/H |

| Material: | 304 Steel |

| Weight: | 2200kg |

| Power: | 11kw/15kw 380V/220V, 50Hz/60Hz |

| Name: | Margarine Artifical Milk Cream Shortening Equipmen |

| Customized: | Customized |

| Application: | Margarine Artifical Milk Cream Shortening |