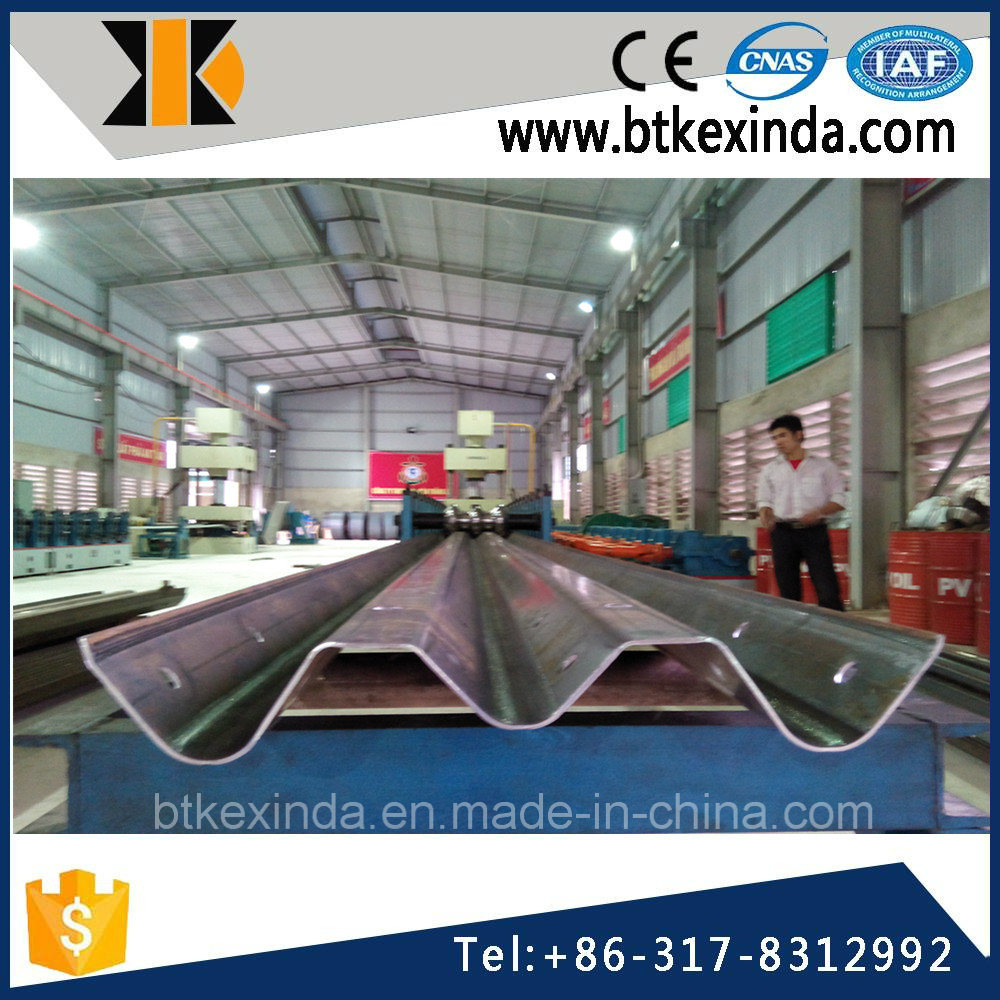

KXD galvanized steel highway guardrail roll forming machine

Equipment components:

Man-made uncoiler, Roll forming machine, computer control system, hydraulic control system, cutting

Our products are widely used in various industrial factory, civilian building, warehouse and easy steel building manufacturing, and have features such as nice appearance and durable.

1. Main parameters of highway guardrail machine

| Main parameters of highway guardrail machine |

| | Suitable to process | Color steel plate, galvanized sheet,aluminum coils and etc. |

| 2 | Effective width | 310mm |

| 3 | Roller station | 17 rows forming

7 roller leveling |

| 4 | Thickness of feeding material | 2.0-2.5 mm |

| 5 | Productivity | 8-12m/min |

| 6 | Rollers' material | 45# forging steel |

| 7 | Diameter of shaft | 100mm |

| 8 | Cutting tool material: | GCr12 with quenched treatment 60-62°C |

| 9 | Weight | About 6.9T |

| 10 | Size | 13.5*1.85*1.6mm |

| 11 | Voltage | 380V 50Hz 3phases |

| 12 | Wall thickness of main forming machine | 14mm steel plate |

| 13 | Main forming machine body | 300 mm H steel |

| 14 | Total power | 22+11 kw |

| 15 | Leveling power | 2.2 kw |

2. Processing technique and deployment

Processes: 10T Hydraulic de-coiler-Leveling device--Punching station--Roll forming machine-PLC system-Hydraulic system-Cutter-Output table

3. Technical Specification

(1)Hydraulic de-coiler: max.capacity: 10T;

(2) Hydraulic System: Power of the oil pump: 11kw Hydraulic oil :40#

(3)Computer control cabinet :

It adopts Delta PLC to control(PLC brand can be changed as your requirement).

The target piece length is adjustable and digit of it can be adjusted

Computed mode has two modes: automatic and manual one.

Processing precision : within 1.00mm

It contains liquid crystal screen, programmer, transformer for the electronic machines and kits of every part.

Transmission chain is1'';

Reducer is Xingxing Cycloid which works stably and no noise

(4)Counter: One counter gauges length, pulses, and decides length

(5) Output table: It used to load the forming plate

ADVANTAGE

| | Our machine | Influence of the machine |

Main forming

machine body | High strength H350 or H400 steel.

machine through milling machine after

welding | Sturdy and durable,

ensure the plate standard |

Material of the

roller | High grade No.45 forged steel | Ensure the forming effect of

the panel and the use age will

be longer,the surface of the panel |

Material of the

cutting | GCr12 steel with quenched treatment | Cutting is out of shape not easily

and use age will be longer,the panel

size precision |

Material of the

active shaft | High grade solid No.45 carbon steel,

Shaft diameter is 72mm. | Improve the integrated mechanic

feature of the shaft and keep product

standard |

| Control system | PLC control system,some elements are

imported from Japan and Germany | Machine become more accurate and

more stable |

Our company supplies different kinds of products. High quality and favorable price. We're pleased to get your Inquiry and we will come back to as soon as possible. We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective.

Kexinda Roll Forming Machine Co., Ltd. Located in Botou - "the famous town of casting molds", enjoying convenient and effective transportation for being close to No. 104, 106 national road and having Jinghu, Shihuang high speed way through all the area, is the professional manufacturer of metal sheet cold roll forming machines for many years.

Advanced and complete equipment is the best commitment for our customers. We not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C-shape purline machines and precipitator anode plate forming machines, etc. We have developed automatic production lines of roll forming machines, roof panels, wall panel forming machine series, glazed tile roll forming machine series, floor deck roll forming machine series, highway barrier forming equipment, double-deck color steel tile roll forming machine series, C and Z-shape steel purline machine series, arc camber machine series, cutting machine and bending machine series, and insulated sandwich panel machines on the basis of traditional roll forming machines. Our machines enjoy a leading position in counterpart industry in China and have garnered nice praise from old and new clients by their good-looking appearance, fair frame and standard model.

Strong technical resource is the most stable guarantee for the quality of our products. We adopt computer software to make design drawing, production drawing and installation drawing for steel construction equipment. We own excellent machining physics laboratories, non-destructive testing equipment and chemical analysis laboratory. We adopt advanced computer digital inspection and produce high-quality light steel structure equipment.

The expansive market is the most powerful testimony that our company is of strong strength. Our products sales cover the whole regions of China, and the products are also sold to Russia, Africa, Southeast Asia, Mediterranean, Middle East, South America and dozens of countries and regions. We have many years of export experience, and we are very clear about the different requirements between developed countries and developing countries. We have the excellent foreign trade team to respond to your questions immediately. The designer can provide the best design scheme according to your intention. The skilled construction staff will produce the machine precisely. We have provided mass customers with satisfactory solutions and established long-term strategic cooperation relationships.

Excellent and professional sales team will supply you the most perfect service system. We have a detailed manual book and can offer you technical support through phone and network. If necessary, we can supply you local technical support. If you need the spare parts of the machine, we will be willing to help, and the real cooperation relationship will not end on delivery.

With the principle of credibility first, mutual benefit and honoring commitment, we can achieve win-win situation.