Categories

Categories

| Price: | US $ 5-1000/Piece |

|---|---|

| Min Order: | 2/Piece |

| Pay Type: | T/T,Western Union |

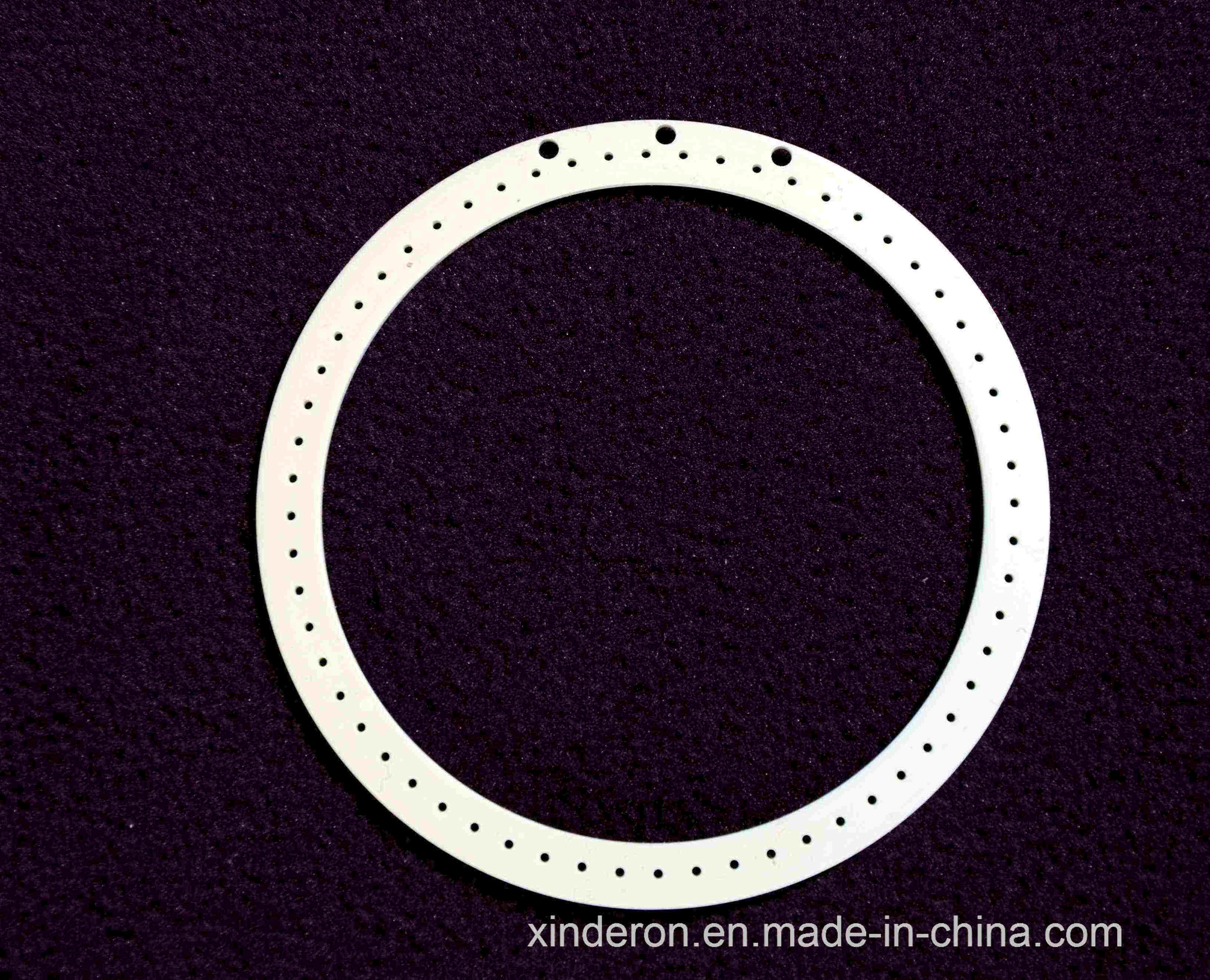

Pyrolytic Boron Nitride Ceramic

Pyrolytic Boron Nitride (PBN) is an anisotropic, high-temperature ceramic which exhibits a unique combination of high electrical resistance and good thermal conductivity.

This non-toxic, non-porous compound is exceptionally pure by virtue of the synthesis process (high temperature/low pressure chemical vapour deposition).

It can be deposited or easily machined into a limitless number of components.

PBN's directional thermal conductivity provides excellent 'heat spreading' capability for improved temperature uniformity.

With its high strength, good thermal conductivity, and a low coefficient of thermal expansion this makes the material extremely resistant to thermal shock.

PBN has found wide acceptance in the semiconductor, electronics, metallurgical, thin film, and pharmaceutical industries.

Features

1. Good thermal conductivity, low coefficient of thermal expansion

2. High insulation resistance

3. Good shock resistance

3. High temperature resistance, maxium working temp 2200ºC

4. High electrical resistance, high dielectric strength

5. Non-toxic

6. Non-wetting

Applications

1. Crystal Growth

2. LEC, VGF and Bridgman crucibles,etc

3. Heating elements

4. Microwave application

5. Semiconductor component

| Item | Value | Unit | |

| Lattice constant | a:2.504×10-10 c:6.692×10-10 | μ m | |

| Density | 2.0-2.19 | g/cm3 | |

| Resistivity | 3.11×1011 | Ω·cm | |

| Tensile strength(ab) | 153.86 | N/mm2 | |

| Bend strength | c | 243.63 | N/mm2 |

| ab | 197.76 | N/mm2 | |

| Elastic modulus | 235690 | N/mm2 | |

| Thermo conductivity | "a" direction "c" direction | ||

| (200ºC) | 60 2.60 | W/m·k | |

| (900ºC) | 43.70 2.80 | W/m·k | |

| Dielectric strength(at room temperature) | 56 | KV/mm | |

Our Services

Why choose us?

We are specialized advanced technical ceramics manufacturer,who have founded 8 years.The quality and service of the products are guaranteed.

We provide customized parts according to user's requirement.We produce and process non-standard components to satisfy the customer's need.

Pre-sale service: Professional technical persons will choose suitable materials for you due to using environment about the ceramic parts.

The sale of services: If you need,we can provide the sample for you to go on testing,and also provide technical help and supports for you.

After-sales service: Accept any repair of the product, help to improve technology for customer. And also provide long-term technical help and support for you!

FAQ

1. How can I get an offer?

You can send your drawing with technology requirements and inform your purchase quantity. If possible, please inform what is your part used in. We will confirm what is the most suitable material and quote our best price to you in 24 hours.

2. Can you provide the free samples?

Yes, we can provide the sample free of charge if we have the stock product the same as what customer required, but the freight is on your side.

3. Can you accept OEM & ODM?

Yes, we can produce the products according to your demand and drawing.

| Prod Model: | N/M |

|---|---|

| Product Name: | Pyrolytic Boron Nitride Ceramic |

| Color: | White |

| Advantages: | High Insulation Resistance |

| Surface: | No Cracks, No Chips, No Bubbles |

| Material: | Ceramics |

| Style: | Chinese |

| Function: | Thermal Insulation |

| Making Method: | Machine Made |

| Usage: | Construction |

| Type: | Customized Shapes |

| Raw Material: | Boron Nitride Ceramic |

| Technique: | Pressing and Machining |

| Theme: | Industrial |