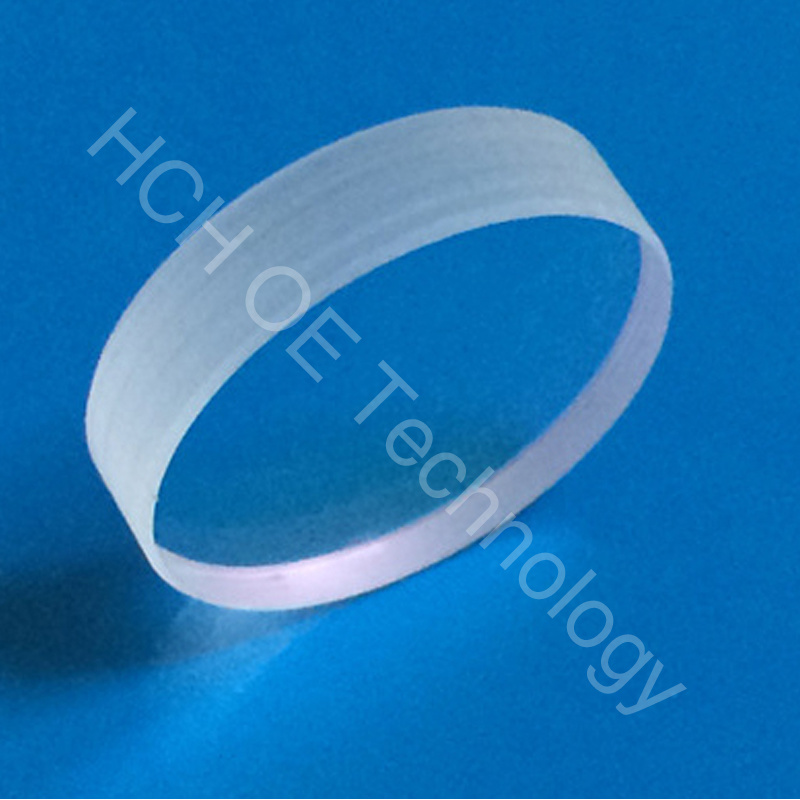

High QualityΦ 25.4*2mm Sapphire Windows From China

| Price: |

US $ 4-6/Piece |

| Min Order: |

1000/Piece |

| Pay Type: |

L/C,T/T,D/P,Money Gram |

Features: - Ø25.4*0.3-6mm Versions Offered

- Uncoated Wavelength Range: 150 nm - 4.5 µm

- Available with AR Coating for 1.65 µm - 3.0 µm or 2.0 µm - 5.0 µm on Both Sides

- Stable Performance over a Wide Temperature Range

Our Sapphire Precision Windows are available in 1/2" to 6" diameters. The uncoated versions are designed for applications in the 150 nm - 4.5 μm range. AR-coated windows feature anti-reflective coatings designed for 1.65 µm - 3.0 µm (-D) or 2.0 µm - 5.0 µm (-E1) on both sides. Uncoated sapphire provides exceptional surface hardness and a transmission range extending from the UV to the MIR. It can only be scratched by a few materials other than itself. The uncoated substrate is chemically inert and insoluble to water, common acids, or alkalis at temperatures up to ~1,000 °C. Our sapphire windows are z-cut so that the c-axis of the crystal is parallel with the optical axis, removing birefringence effects on transmitted light.HCH also offers precision windows fabricated from several other substrates for use in a large variety of laser and industrial applications. For our complete selection, see the Precision Window Selection Guide table to the right. We also offer laser windows, which have AR coatings centered around commonly used laser wavelengths, and Brewster windows, which are designed to eliminate p-polarization reflectance.| Precision Window Selection Guide |

| Wavelength Range | Substrate Material |

| 150 nm - 5.0 μm | Sapphire |

| 180 nm - 8.0 μm | Calcium Fluoride (CaF2) |

| 185 nm - 2.1 μm | UV Fused Silica |

| 200 nm - 6.0 μm | Magnesium Fluoride (MgF2) |

| 250 nm - 1.6 µm | UV Fused Silica, for 45° AOI |

| 300 nm - 3 µm | Infrasil® |

| 350 nm - 2.0 μm | N-BK7 |

| 600 nm - 16 µm | Zinc Selenide (ZnSe) |

| 1.2 - 8.0 μm | Silicon (Si) |

| 2.0 - 16 μm | Germanium (Ge) |

| 3 - 5 μm | Barium Fluoride (BaF2) |

| V-Coated Laser Windows |

Sapphire Characteristic:

Good transmission over the visible and near IR spectrum,

The optical transmission is high with little or no distortion of the transmitted signal.

High mechanical strength,

Temperature stability,

Wear resistance

Chemical inertness.

Application:

Air and Gas Analyzers/Monitors, Cryogenic View Ports, UV and IR Windows and Lenses, Detector and Pressure Cells, Bar Code Readers.

Sapphire has a transmission from 190nm to 5300nm and is very strong compared with other optical materials. Sapphire windows can be used at very high temperatures, up to 2000°C.

Sapphire has excellent strength and abrasive resistance which enables it to be used in the form of very thin windows and extremely harsh environments. Sapphire is often used for pressure windows or port windows where conditions are severe such as sandy, salty environments where a softer BK7 window would quickly scratch and become unusable.

| Coat: |

Non-Coating |

| Lenses Color: |

Transparence |

| Type: |

Sapphire |

| Coating: |

Mirror |

| Material: |

Ky Sapphire |

| Shape: |

Round |

HCH Optoelectronic Co., Ltd. (HCH) are try to been a leading supplier of optics and optical components to industry since 2013, designing and manufacturing a wide array of multi-element lenses, lens coatings, imaging systems, and Opto-Mechanical equipment. LED by a staff of skilled optical engineers and scientists, HCH is application focused and pursues new ways to implement optical technology, enabling advancements in semiconductor manufacturing, industrial metrology, and medical instrumentation. Our precision products improve efficiencies & yields and are used in test & measurement quality assurance applications, the automation of manufacturing processes, and research.

We are a worldwide presence in industrial optics extending well beyond our original manufacturing plant. Our expanding international presence includes sales offices in: Japan, China, Germany, the United Kingdom, France, Singapore, South Korea, Israel, and Switzerland.

HCH's engineers are uniquely qualified to provide a variety of application integration services to our customers and can create ideal solutions for your optical challenges by integrating products from our broad off-the-shelf inventory. When immediate use of off-the-shelf products is not possible, HCH's engineers can often modify existing products, using our extensive manufacturing resources to create products that meet unique customer needs. Along with our ability to design and manufacture a wide variety of optics and components, HCH can manufacture Opto-Electronic and Opto-Mechanical subassemblies to meet our customers' demanding requirements.

Our capabilities include:

High Precision Magnetorheological Finishing for Lenses and Prisms

Opto-Mechanical Assemblies

Opto-Electronic Assemblies

CNC (Computer Numerically Controlled) Lens Grinding and Polishing

Precision CCD Optics

Optical Component Manufacturing (0.5 to 100 mm Diameter)

Flat, Spherical and Parabolic Mirrors

Prism Manufacturing (0.5 to 75 mm)

To maintain higher levels of production quality and accuracy, our facilities feature modern equipment, including:

Zygo GPI-XP4 Phase Shift Interferometers

Test Equipment

Grinder

Polisher

Four Spindle Polisher

10J Edge Grinder

Centering Machine

HCH are try to been a leading design and manufacturing source in the optical industry since 2013, providing a wide array of multi-element lenses, lens coatings, imaging systems, and optical positioning equipment.